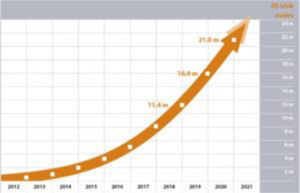

Svært positiv utvikling

IO-Link har nådd et kritisk utviklingspunkt

Rådende trender; Den positive oppadgående trenden med IO-Link fortsetter. Ikke minst viser det seg i nyinstallerte noder. Antall installasjoner i 2000 er nå godkjent. Sammenlignet med 2019 har antallet økt med 31prosent, og har nådd omlag 21 millioner noder ved utgangen av 2020. Tatt i betraktning at året var preget av en pandemi med tilsvarende økonomisk innvirkning, er denne utviklingen svært positiv.

Av Reinhard Schlagenhaufer, Leader, IO-Link Working Group

Fakta:

IO-Link er en standardisert IO-teknologi (IEC 61131-9) for kommunikasjon med både sensorer og aktuatorer. Denne effektive punkt-til-punkt-kommunikasjonen er basert på den kjente tretråds sensor- og aktuator-tilkoblingen, og stiller ingen ytterligere krav til kablingen.

Resten av artikkelen er ikke oversatt.

Future-Ready

A rising number of machine and plant manufacturers are therefore using IO-Link as a modern interface for connecting sensors and actuators. The trend toward Industry 4.0 will further strengthen this path to communication, even down at the field level. The importance of condition monitoring and predictive maintenance will grow, and the need to obtain additional information for quality assurance and the optimization of entire manufacturing processes will become increasingly important. Information such as temperature and humidity in the environment of a manufacturing process are examples that, combined with the direct manufacturing process and possible incidents, offer conclusions about optimization possibilities.

In the future, sensor data will not be processed exclusively in the controller. It will also be available for cloud and edge devices, for example, to perform analyses in addition to pure production control. Furthermore, the configuration and status query of sensors and actuators should be possible using a tablet and/or smartphone. To enable IO-Link to serve these IoT interfaces, the mappings to OPC UA and JSON have already been standardized. Integration into PROFINET has been further improved. IO-Link and PROFINET are a successful duo with high growth potential.

New Initiatives

The IO-Link community, which has been focused on further developing the following topics, therefore sees itself as strengthened in its strategic alignment to develop IO-Link ever more efficiently while remaining user- and operator-friendly. More and more actuators and sensors are needed to tap into applications in quality assurance and process optics, In addition to the classic sensors in factory automation, applications for IO-Link in signal lights and other systems (e.g., weigh scales) are also in development. Transducers for inclination, oscillation, vibration, temperature and humidity that include IO-Link are also on the rise. Sensors are increasingly becoming smart sensors. In addition to the necessary profiles, handling must remain as simple as possible here.

IO-Link supports the user, for example, with the IODDfinder, which provides the necessary device description at the click of a mouse. A further development in this context is the IODDviewer, which transparently displays the functions of a device. Device manufacturers and users benefit from these functions.

IO-Link Safety, for example, also expands the areas of application, while offering the long-awaited possibility to use IO-Link for functionally safe applications.

The community naturally continues to address the right issues for the future.

The topic of IO-Link Wireless has been in discussion for quite some time now. Initially, the focus was on limited applications for the connection of IO-Link sensors when the options for wiring are limited or not available at all. IO-Link Wireless could open up the possibility of the completely wireless automation of entire modules in a mobile environment – a rather bold approach.

In order to keep the associated basic specification up to date and synchronize it with IO-Link Safety and IO-Link wireless, Package 2020 was adopted.

Undeniably, Single Pair Ethernet will make waves in the entire automation technology market and is therefore another topic that the IO-Link community will take on.

The various, successful workshops held by the international regional IO-Link communities around the world also clearly underscore the international acceptance of IO-Link.

Aggreko øker batteriinvesteringene til 200 millioner dollar for å støtte energiovergangen

Aggreko har økt sine globale investeringer i mobile batterilagringssystemer (BESS) til rundt 200 millioner dollar, slik at flere bedrifter kan få tilgang til den nyeste batteriteknologien og nå sine mål om netto nullutslipp.

Ny Emerson Flushing Ring

TESCOM AGI Flushing Ring fra Emerson med modulær montering for bruk ved skylling. Ved å gi en fullstendig og modulær ventilmontering med et enkelt delenummer effektiviserer skylleringen i AGI BR-serien bestilling og legger til rette for enkel bestilling på nytt med bestemte testkrav fra kunder. Både de tradisjonelle ringene i BRS «sandwich»- og BRW «wafer»-stil er tilgjengelig, samt BR7-designet i «integrert deksel», som omfatter lufting/skylling i selve flensringen.

Ny kraftig SCARA-robot fra KUKA

– raske bevegelser og 60 kg nyttelast. KUKA lanserer nok en SCARA-robot denne høsten. En kraftig modell med en maksimal nyttelast på 60 kilo. SCARA-roboter har flere fordeler. De er energieffektive, kostnadseffektive og kan bevege seg raskt med svært høy presisjon, sier Micael Amandusson, channel manager hos KUKA Nordic.

Neste generasjon PLS teknologi

Beckhoff muliggjør et reelt sprang i ytelse innen automasjonsteknologi med TwinCAT PLC++. Både utvikling og hastighet kan akselereres, samtidig som de velkjente fordelene med TwinCAT, som konsekvent integrasjon, kompatibilitet og åpenhet, fortsatt leveres.